Continuous Improvement - Equipment Department in Action

Release date:2018-09-04

In the first half of 2018, under the leadership of general manager Xu, focusing on the theme of lean production and the background of continuous improvement of the company, all staff of the equipment department actively participated in and participated in the company tide of working environment transformation, and with the help of colleagues from the financial department, the management and management process of spare parts was re optimized. To sort out and bring the basic management work and institutionalized operation of the equipment department into a step-by-step stage, so that the equipment department's maintenance skills, equipment management capabilities and standardized operation of various processes can be greatly brought into play, while the timely repair time and reaction time of equipment failure are more competitive, and strive to become the production department. Strong logistical support.

1. Optimal management and sound process control of spare parts 1.5S improvement.

After improvement, clean and spacious spare parts storehouse and storage rack.

2. The Finance Department takes the lead in making clear management identification cards for spare parts according to different types of planning.

3. Optimized spare parts management, tool management and a series of management processes.

Procedures for requisition and warehousing shall be carried out according to the procedure.

Classification, inventory and hanging of material control cards.

Establish the account of all materials in the warehouse, arrange neatly and mark well according to the management requirements, so as to achieve the consistency of account, card and material.

Responsible for the storage and protection of materials in warehouse, and the receipt and distribution of materials in and out of warehouse according to the prescribed procedures.

By using the above optimized management regulations, the shortcomings and impacts caused by some defects in spare parts warehouse are initially properly and effectively solved. To a large extent, it stimulates the confidence of spare parts managers, improves the intact rate of equipment, reduces the waste of maintenance time and improves the operation process, and improves the quality of maintenance leaders and managers.

2. Improvement of the Environment and Management of Air Compressor Room.

The renovation of the air compressor room has enabled the air compressor to have a better working environment and to provide efficient and clean energy-saving air source for production. Provide strong guarantee for safe and efficient production.

From the following points to carry out special management of the computer room.

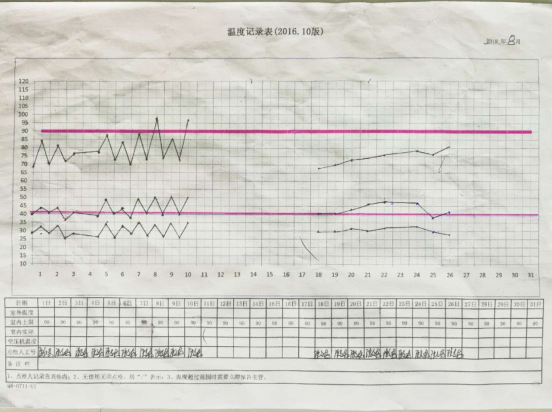

1. Monitor and manage the temperature (outdoor temperature, indoor temperature, equipment operating temperature) and humidity in the machine every day.

2. Unobstructed Heat Source Exchange Channel.

3. Clean and concise operating environment is the cornerstone of providing clean air source.

4. Regular Maintenance Standards and Safety Management System.

Last article:Continuous Improvement - the base of company development

Next article:Equipment cleaning by manufacturing