Intelligent manufacturing,We are on our way.

Release date:2019-12-10

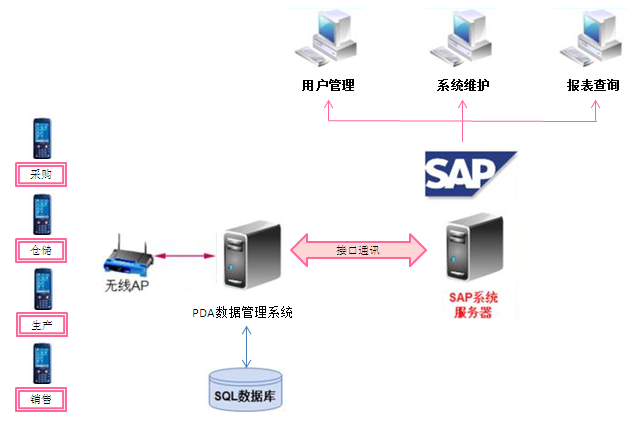

Now intelligent manufacturing has become the development trend of enterprises. The traditional manufacturing industry is transforming and upgrading from automation to intelligent. In the process of intelligent manufacturing system construction, the integration of industrial automation and informatization requires the interconnection and intelligent collaboration of production information. I The company also kept pace with the times, introduced a barcode management system, and seamlessly connected with the newly upgraded SAP to achieve production informationization and digital management.

The SAP team has developed a mature warehousing and production management system tailored for our company after in-depth in-depth investigations, business process reengineering, custom development, and testing. It has been officially launched for six months.

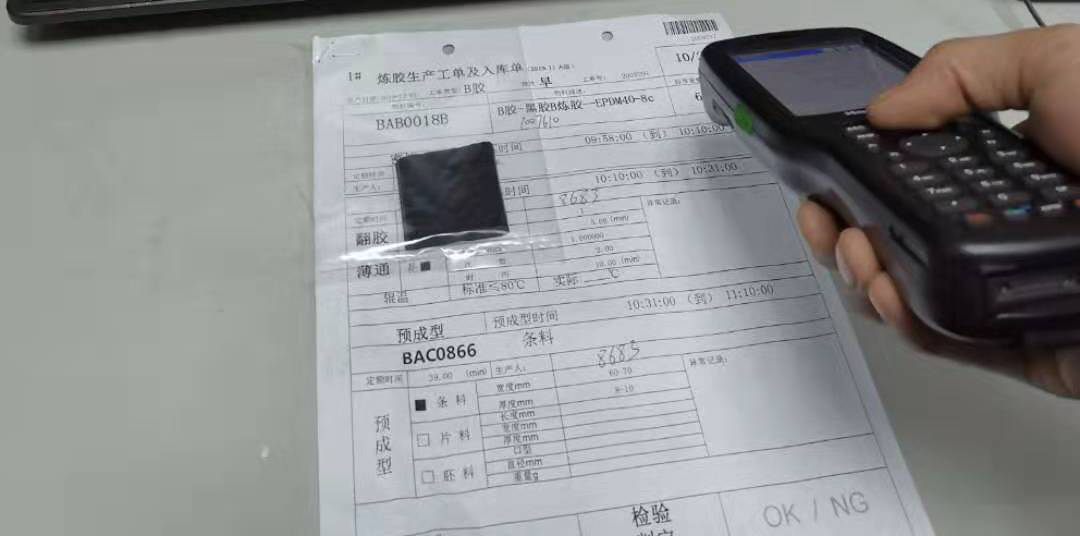

1 Barcoded job management throughout the process

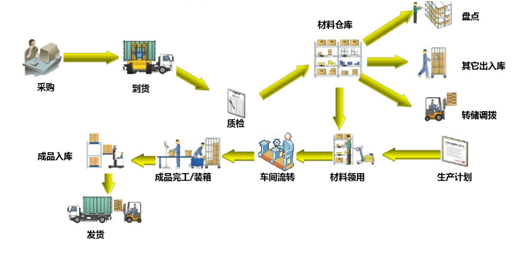

Through the introduction of PDA data collection, accurate management of batches of raw materials and other purchased storage, input batches of related raw materials, and product related raw material and finished product input batch information, follow-up sales follow-up batch tracking. Accurately achieve the batch traceability goal from finished product → finished product → raw material → supplier.

2 The whole process online inspection

The original paper inspection benchmark was entered into the PDA system, and the system made its own judgment based on the actual measurement results. It realized the online inspection and judgment including the warehousing inspection of raw materials, finished products, and finished products, and the inspection of each production process. This improves the accuracy and timeliness of the test.

3 Intelligent warehouse management

Add intelligent location management and control. Scanning the location will bind the materials to the location. The material delivery system automatically associates the batches of materials and strictly controls the FIFO requirements of the materials. Improve the quality of warehouse inbound and outbound management.

Real-time data collection, data synchronization with the system, reducing the manual entry process, making front-line operations more portable and efficient, and significantly improving SAP's on-site management and control of materials and production processes, and strengthening product (personnel), machines (equipment) ), Material (input material), method (production technology), and environmental (production environment) quality control. After running for a period of time, the application effect is quite good, the running speed of each link is improved, and the overall production and management efficiency is further improved. Intelligent manufacturing, we are on the road.

Last article:New technologies lead to product enrichment and progress

Next article:Continuous improvement and efficiency