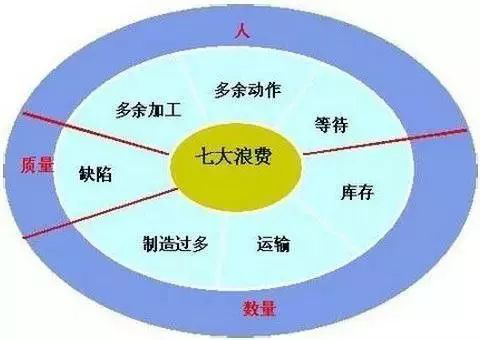

Seven ways to Eliminate Waste from Lean production

Release date:2020-06-06

It is very difficult for domestic enterprises to achieve lean production. It has been five years since we learned from the first batch of Toyota headquarters in Japan. Among the same batch of enterprises, few have succeeded in implementing lean production, and even fewer can persist in it.As a private enterprise, we have deep experience, fortunately, we became the one to stick it out.

Why many companies insist on not down, is the enterprise environment, atmosphere, every year since 2015 the company transferred backbone participated in training of lean production in Japan, various departments in 2017 Japan's adviser to the scene teaching, change the lean production mode to village mode of production, from a little bit of progress every day, to the participation of improvement, one step at a time, laid a solid foundation.Lean production focuses on continuous improvement, and this year's theme is to eliminate seven major wastes and eliminate all non-value-added activities.

Each department identifies the waste phenomenon according to its own business scope, thus establishing work topics, formulating work requirements, setting work objectives and carrying out specific implementation.

1.Eliminate the waste of waiting

The waste of waiting is the waste of idle resources such as personnel and equipment.There are still a lot of waiting situations on the manufacturing site. According to different processing characteristics, corresponding improvement measures should be taken in each production process to minimize the waiting phenomenon.Rubber mixing production is an assembly line operation, mainly based on equipment production, with one person and many posts. Meanwhile, production scheduling order is optimized to achieve process balance, so as to reduce waste of equipment and equipment.Molding production for a single machine operation, internal and external production line to achieve a multi-machine production mode.In order to eliminate waste, the finishing team adopts the method of pressing first and checking first to shorten the working time.

2. Eliminate waste in handling

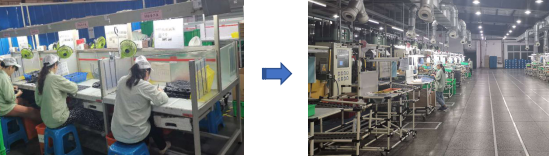

Any movement of material is a waste.The manufacturing department changed the original practice of centralized transfer to the next workstation after all the products were formed into a flow production mode, that is, after the products were formed, they were repaired, checked and packaged along the line, and then directly put into storage, which greatly reduced the carrying distance

Centralized repair and inspection of original products Now follow the line check

3. Eliminate waste of defective products

In order to further improve the production quality of products and advocate the quality concept of "no acceptance, no production, no outflow of defective products", the Manufacturing department strengthened self-inspection and the quality control department strengthened patrol inspection.The occurrence bad namely stop, immediately assemble relevant personnel spot ameliorates.In addition, for the difficult products, select TOP3 to put on record, set up an improvement group, and carry out the project solution.Good results have been achieved so far, and the yield rate has been rising steadily.

4. Eliminate movement waste

Any movement of people and equipment that does not add value to the product is wasteful.The manufacturing department standardized the operating methods of rubber refining, forming and finishing processes, in order to shorten the distance, use both hands at the same time, reduce redundant actions and other economic principles of action, split, merge and recombine the existing actions, establish standard operating actions, and measure the production beat.

5. Eliminate processing waste

Redundant processing is a waste of time and production equipment.Also includes the product quality surplus is also a waste of processing.Manufacturing department will adjust the process route of some products, the process reorganization, merger, such as special process of products, the original process is shaping - trimming - secondary vulcanization - inspection, instead of shaping - trimming - inspection - secondary vulcanization, in order to achieve along line operations.The quality control department establishes the limit sample of all products and further clarifies the standard to prevent the waste caused by excessive excellence in the operation process.

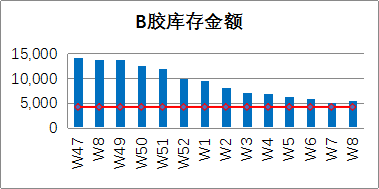

6. Eliminate inventory waste

Any supply that exceeds the customer's (including the post-process) needs will result in a build-up of inventory and waste.At present, we adopt the method of small monochemical production scheduling to reduce inventory, that is, the finished products are arranged according to demand instead of one car (complete car mixing), and the small equipment is used for less quantitative production.Finished products are also broken before the shift as production scheduling unit, gradually adopted by the hour production scheduling.This has significantly reduced production inventories.

7. Eliminate excess production waste

Waste producing more than or faster than demand.Production (time and demand) should be completely scheduled according to demand, without considering abnormal factors, such as product defect rate, equipment failure, personnel absence, etc., in this way, abnormalities can be fully exposed for better solution.At the same time, if the production is too early, the production costs will be used up in advance, but also occupy the capital.For this reason, the supply chain department has also formulated a new production scheduling plan and locked the production plan, which is being gradually optimized.

The guiding principle of lean production is to eliminate all waste. Nowadays, the activity of eliminating waste is everywhere in our company, and the concept of continuous improvement has been deeply rooted in people's mind.The promotion of lean production mode, we step by step, steady, every improvement let us closer to success, we will be more determined to go forward.Every step of the way counts.