A brief discussion on the error-proof management of the company

Release date:2020-08-17

"Do not accept defective products, do not produce defective products, do not flow defective products," this is our product quality requirements, but also a commitment to customers.

For the manufacturing industry, the most worrying is the occurrence of quality accidents or safety accidents, and "man-machine material method ring" each link may lead to defects.In these five links, the human factor is particularly important, because human error will also affect the machine, material, law, environment and other factors, after all, things are done by people.In this way, how to prevent the occurrence of human error has become a very important topic in our work to control product quality.

In the past, we have achieved some results by training our operators in "conscientiousness", "safety awareness" and "quality awareness".However, the mistakes caused by human negligence and forgetfulness cannot be completely avoided.Later, we found that mistakes should be eradicated from the root. Instead of relying solely on employees' autonomy to control mistakes, some necessary tools should be adopted to reduce the occurrence of mistakes.Here are some of our applications for error prevention:

1. Insurance principle: more than two actions must be performed together or in turn to complete the work.

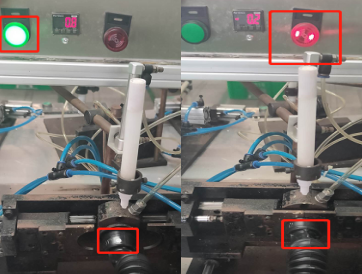

Case: The employee operating the molding equipment did not take out his hand or finger in time, which caused the injury.After such work-related injury accidents, we designed the molding equipment to work normally when starting automatically by pressing the start button with both hands (so as to avoid the staffs forgetting one hand under the mold). At the same time, we also set grating protection in front of the mold, so as to double-insure the staffs' safety.

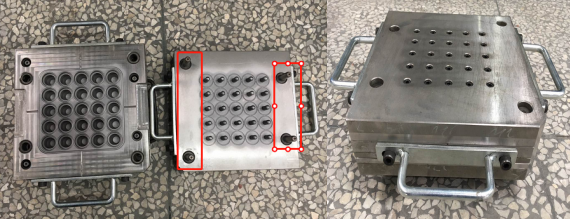

2. Root cutting principle: to fundamentally eliminate the causes of errors and eliminate the occurrence of mistakes.

Case: All molds of the company will have positioning pins to prevent errors. Positioning pins at different levels or at the same level are designed to be of unequal structure to prevent errors in mold installation.

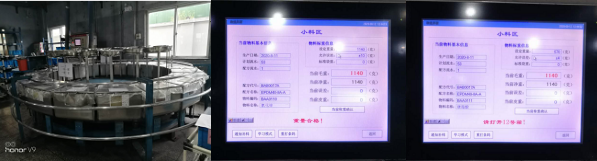

3. Principle of automation: Automatic equipment is used to limit or remind the execution of certain actions to avoid errors.

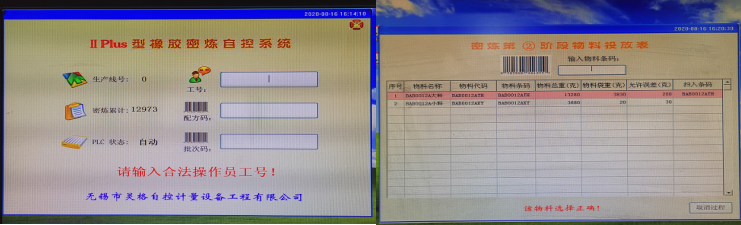

Case: in the mixing mixing system, the equipment will automatically turn the next material to the batching staff only after the current material weighing is accurate, allowing the next material weighing to continue. Otherwise, the equipment will stop running and the other material boxes cannot be opened.

4. Principle of sequence: Avoid inversion of the sequence or process of work. It can be arranged according to the number sequence.

Case: the rubber mixing and error prevention system, only when the material species and feeding order are correct premise, can open the equipment feeding door, carry out intensive automatic operation.

5. Isolation principle: To protect certain areas from errors by separating them.

Case: No matter in the workshop or in the warehouse, there are special boxes or iron frames with locks for storing defective products, so as to strictly control defective products and prevent them from flowing out.

6. Warning principle: if there is any abnormal phenomenon, the warning can be given in a clearly marked way.

Case: (1) When the material storage of the injection machine is insufficient or the temperature deviation is large, the equipment will have a red light alarm display, the equipment will stop running;

(2) to be gas inspection products only in the satisfaction of a certain pressure and a certain holding time, pressure OK equipment will automatically dot, otherwise the red light alarm product gas inspection is not qualified, the equipment will not dot.

Error-proof management can help us avoid the occurrence of bad accidents to the greatest extent in the process.On the one hand, it can reduce customer complaints and improve customer satisfaction; on the other hand, it can also reduce bad losses and reduce costs.On the way of error-proof management, we will continue to explore and improve.

Last article:Feelings on the first anniversary of entering zhengcun

Next article:Is the village characteristic team builds