Eliminate waste and create value

Release date:2022-07-02

If a business is "burning" a lot of money every day, can you expect the business to get the most profit? Some people may say that I have worked so hard to make money, but I can still "burn" money? But in fact, most of our enterprises are "burning" money, but not with fire, but there is a lot of waste in the enterprise, spending a lot of hard-earned money in vain.

"Eliminate waste and create value" is the essence of the core idea of lean production. Only by eliminating waste can value be created. In layman's terms, any behavior that does not create value is waste. Only by eliminating waste and improving continuously can an enterprise maintain a healthy operation and increase its competitiveness.

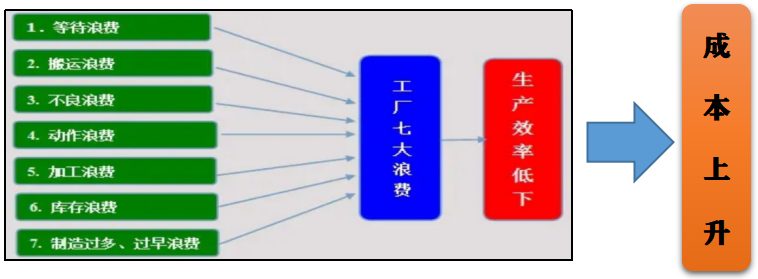

The object of improvement is waste, and understanding waste is the first step in improvement. There are many enterprises on the scene, which are valuable and which are waste. It is not easy for ordinary people to understand at a glance. Toyota has summarized the content of waste in the long-term operation and improvement process, and there are seven types of waste, which are called the seven wastes. They are waiting waste, handling waste, bad waste, action waste, processing waste, inventory waste and excessive (early) manufacturing waste. All waste ultimately leads to low production efficiency and increased enterprise costs.

In order to improve production efficiency and reduce manufacturing costs, we must eliminate these seven wastes in on-site management. Zhengcun Company has done a lot of improvement work on the seven wastes in the field management in the past year:

(1) For the waste of waiting

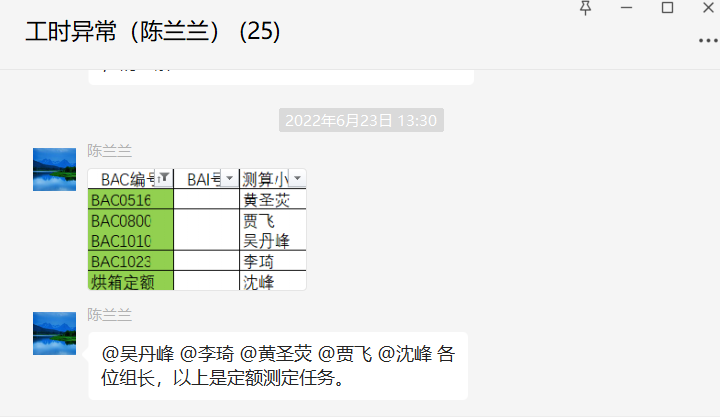

We promoted the re-measurement of product process quotas to ensure the accuracy of the quotas for each process of each product, and then balanced the daily production plan, reasonably controlled the production rhythm, and promoted the operation mode of one person with multiple machines and one person with multiple positions, and minimized the number of personnel, Waiting for equipment and materials.

(2) Waste of handling

We have adjusted the workshop process layout and post process layout:

Workshop process layout adjustment: We re-planned and adjusted the inspection, manual packaging, automatic packaging, machine trimming, frozen trimming, punching trimming, water cutting, automatic painting and gas inspection in the first phase of the workshop to reduce the number of processes. The distance between them can reduce the waste of transportation.

Adjustment of post process layout: implement a one-flow production method in the production line, and implement one-flow production of "pressing repair and inspection package" for most products, so that all the work of molding, trimming, inspection and packaging can be completed in one station, reducing handling of waste.

(3) For bad waste

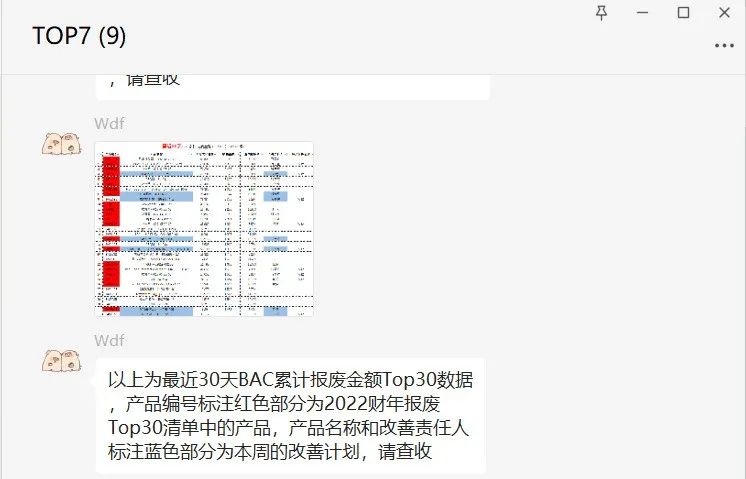

Through the statistics and analysis of historical non-performing data, we set up an improvement team and formulate a TOP7 improvement plan to continuously improve product defects and reduce scrap.

(4) Waste of action

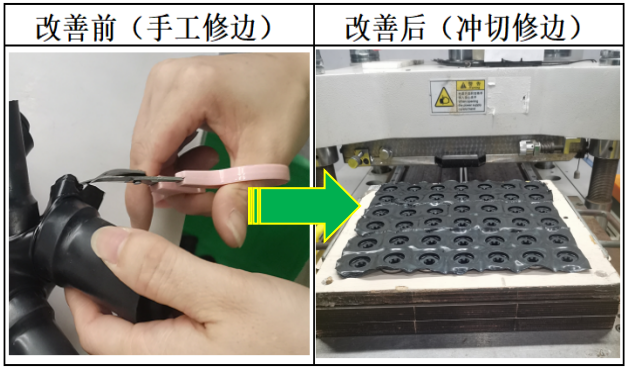

Continuously improve actions that do not produce added value, unreasonable operations, and inefficient postures and actions. For example, for BAC0349 products, in order to improve the trimming efficiency, we changed the manual trimming to punching trimming, which greatly improved the trimming efficiency. edge efficiency.

(5) Waste of processing

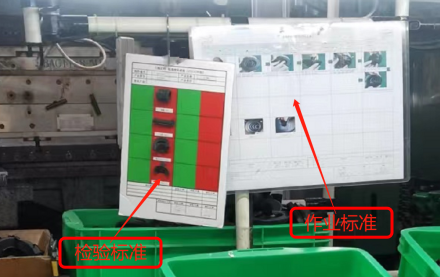

Implement standard operations on the production line, formulate product operating standards and inspection standards, reduce unnecessary processing and inspection, and prevent excess processing and excess quality.

(6) Waste of inventory

Planning level: In order to reasonably control the inventory amount under the condition of ensuring on-time delivery, we have formulated a reasonable inventory control plan through the inventory analysis of suppliers and materials and combined with the master production plan.

Execution level: In the daily production management and inventory management, in order to control the inventory backlog, we have formulated the twelve-character policy of "first refining, first pressing, first inspection, first customs, first advanced, first out" in line with the actual production of Zhengcun. And daily monitor the timely closing rate, the unsettled work hours, the unclosed work orders and the sluggish amount of the warehouse, and timely monitor and feedback timely analysis and rectification.

(7) For excessive (early) manufacturing waste

Break the existing planned production scheduling mode, design a new production scheduling system according to the actual situation of the company, and use the pull-type production method to reasonably schedule production;

Formulate production plan locking rules for customer orders, reduce the number of changes in the plan, and ensure smooth production.

By improving and eliminating the seven major wastes on site, the company has optimized the entire production management system and promoted the continuous development of the company's waste-free production model. All in all, I believe that through continuous improvement and the continuous elimination of the seven major wastes in the production site, our production efficiency will become higher and higher, product quality will become better and better, and manufacturing costs will become lower and lower. The company will also get better and better.

Last article:Father as a mountain

Next article:Opportunities under epidemic situation