Brief discussion on O-ring sealing design

Release date:2024-07-17

O-rings provide designers with a cost-effective sealing element for a variety of static or dynamic applications. Cheap production methods and ease of use make O-rings the most widely used sealing components. Elastomer materials have a wide range of options for both standard and specialty applications. Therefore, the O-ring can be applied to the sealing of all liquids and gases in practical use. The O-ring is vulcanized in the mold, which is characterized by a circular appearance and a ring cross-section. O-rings are available in size specifications: the cross section diameter is about 0.35~40 mm, and the inner diameter can reach 5,000 mm and above.

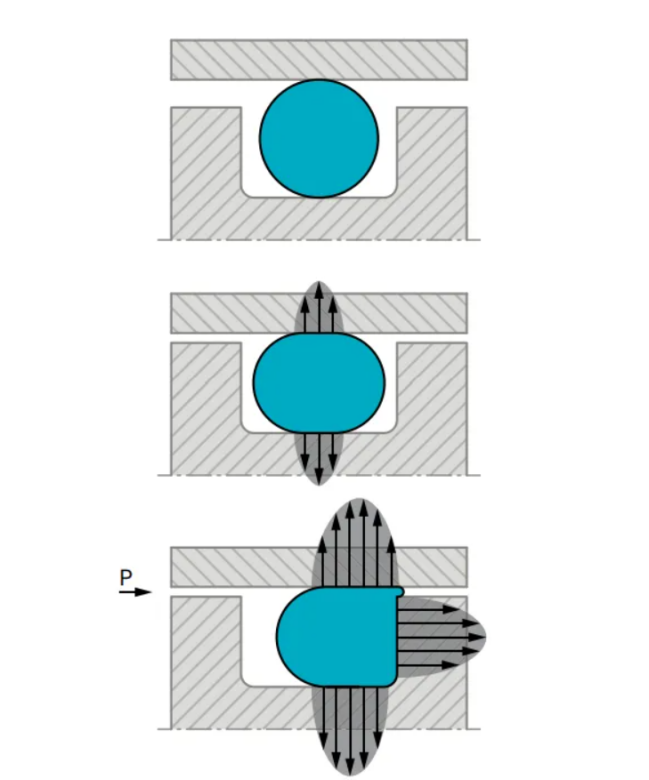

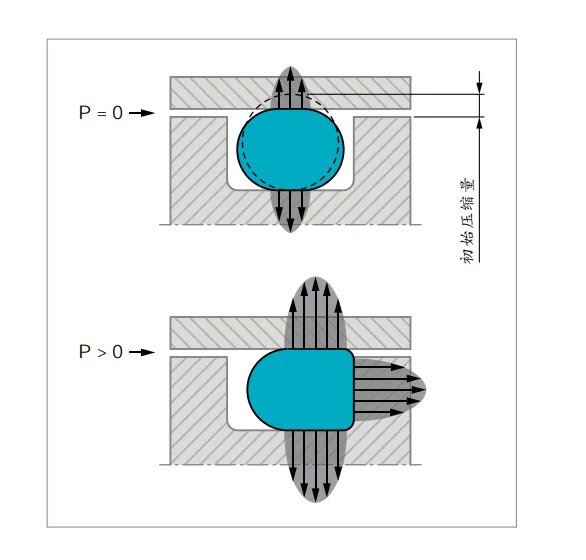

1 Principle of action

O-ring is a bi-directional sealing element. When installed, the initial radial or axial compression of the O-ring determines the initial sealing capacity of the O-ring. The force generated by the system pressure acting on the O-ring is its total sealing force; The sealing force increases with the increase of system pressure. Under pressure, the shape of the O-ring is similar to that of a liquid with high surface tension, and the pressure is transmitted equally in all directions.

2 Working pressure

2.1 Static Application

- Higher than 5 MPa, O-ring diameter >50 mm, without a stop ring;

- Higher than 10 MPa, O-ring inner diameter <50 mm, without stopper (depending on material, cross section and clearance);

- Higher than 40 MPa, without a stop ring; - Higher than 250 MPa, with a special stop ring; - Please note the allowed extrusion clearance.

2.2 Dynamic Application

- Reciprocating movement higher than 5 MPa without a stop ring;

- Higher pressure conditions with retainer. Speed reciprocating motion up to 0.5 m/s Rotary motion up to 0.5 m/s depending on the material and dielectric resistance. Temperatures range from -60°C to +325°C depending on the material and dielectric resistance.

When evaluating application conditions, the maximum value, continuous operating temperature and dry run time must be taken into account. For rotary applications, the result of frictional heat generation resulting in temperature rise must be taken into account. Media for a variety of materials, each has a different performance, in practical applications will basically encounter the sealing fluid, gas and chemical media, please pay attention to choose the most appropriate material.

3 Materials

3.1 ACM (Polyacrylate rubber)

ACM materials have excellent ozone resistance, weathering resistance and heat resistance to air, but their physical strength is moderate, their elasticity is poor, and their resistance to low temperature is relatively weak. ACM operating temperature range is -20°C to +150°C, but can reach +175°C for a short time. Special types of ACM operating temperatures can be as low as -35°C. ACM materials are mainly used in the automotive industry, which has high requirements for being able to resist the corrosion of lubricants containing a variety of additives, including sulfur, at high temperatures.

3.2 EPDM (EPDM)

Epdm rubber has good heat resistance, ozone resistance and aging resistance. In addition, EPDM rubber also has good elasticity, good low temperature properties and insulation properties. Epdm rubber has an operating temperature range of -45°C to +150°C (up to +175°C for a short time). The operating temperature range of the vulcanized EPDM rubber is reduced to -45°C to +130°C (+150°C can be reached in a short time). Epdm rubber is often used to seal brake fluid (ethylene glycol base) and hot water.

3.3 VMQ (Silicone rubber)

Silicone rubber has excellent heat resistance, cold deflection, insulation properties and excellent oxidation resistance, ozone resistance and ultraviolet (UV) resistance. The special silicone rubber material is resistant to gear oil, water above +100°C and high molecular weight chlorinated hydrocarbon media. The operating temperature range of silicone rubber is -50°C to +175°C (up to +230°C for a short time). Special types of silicone rubber can operate at temperatures as low as -90°C.

4 Chemical Compatibility

Before choosing a suitable material, it is important to fully understand the chemical compatibility guidelines. Before selecting a material, all aspects of the application must be thoroughly and carefully analyzed. For example, some corrosive fluids have a more significant effect on synthetic rubber at high temperatures than at room temperature. In addition, the physical properties of the material and its compatibility with fluids should also be considered. Because in a specific application, the compression deformation, hardness, wear resistance and thermal expansion of the material will affect the suitability of the material. Users are advised to test for specific applications to confirm the suitability of the selected material.

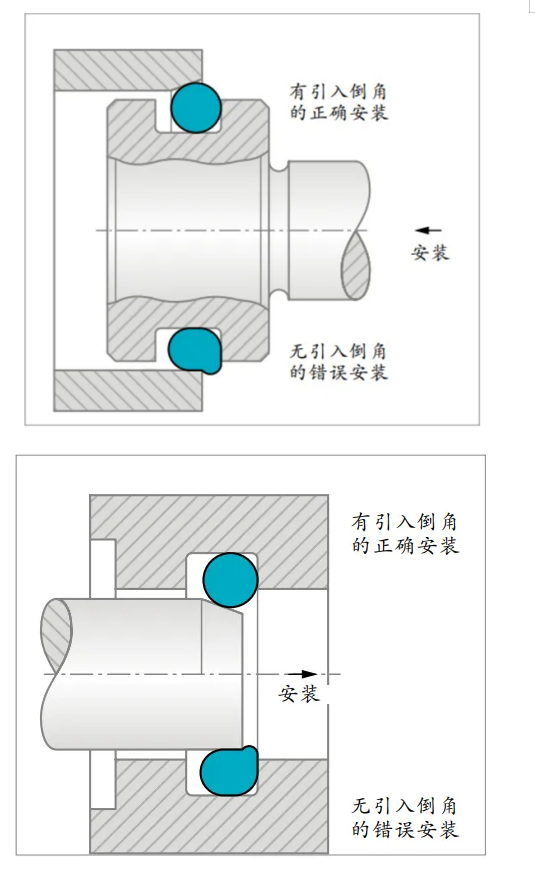

5 Suggestions on installation methods and sealing groove design

During the design phase, the installation of O-rings should be considered. In order to avoid damage to the O-ring during installation, the O-ring should be avoided as far as possible through the sharp edge or the inner hole. When the sliding distance is long, the seal seat should be designed as a groove as possible, or the O-ring should be properly adjusted to ensure that it only needs to slide a short distance during installation to reduce the risk of distortion of the O-ring.

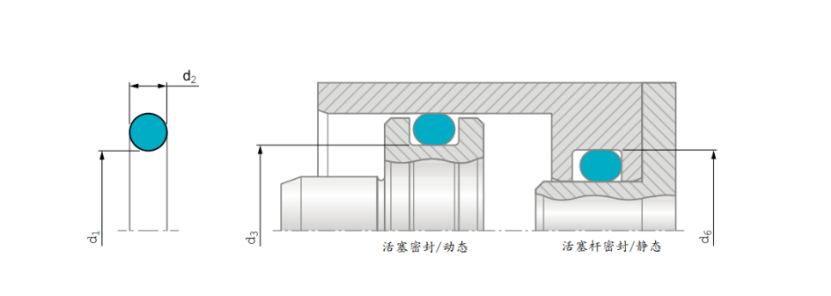

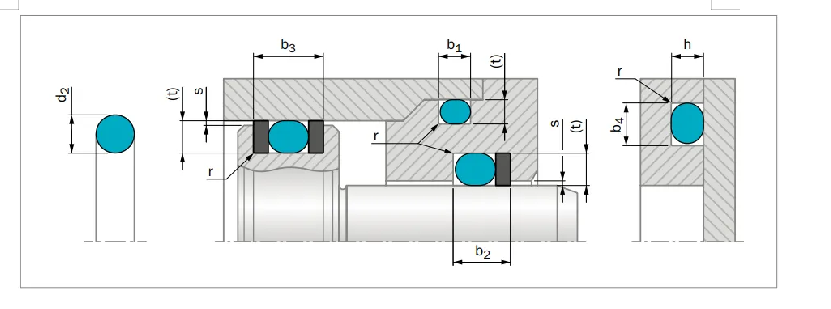

6 Radial mounting (static and dynamic motion) and internal sealing (piston rod seal)

When selecting an O-ring of appropriate size, ensure that its outer diameter (d1+2*d2) is at least equal to or greater than the outer diameter of the groove d6. When selecting an O-ring with appropriate specifications, ensure that its inner diameter d1 is at least equal to or less than the groove inner diameter d3.

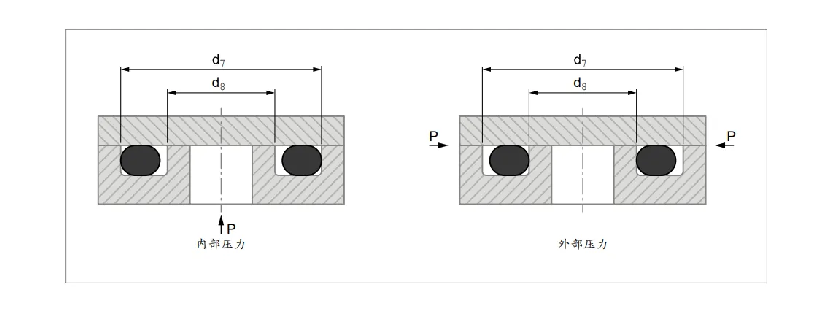

7 Axial installation (static motion)

In the axial static installation, when selecting the appropriate specification of O-rings, the direction of pressure should be considered. When there is internal pressure, the outer diameter of the O-ring should be equal to or greater than the outer groove diameter d7; When external pressure is present, the inner diameter of the O-ring should be less than the inner groove diameter d8.

8 Tensile ratio - outside diameter interference

Radial mounting of piston and piston rod seals under static and dynamic motion

If the O-ring is used as a piston seal, the main O-ring diameter d1 should be stretched by 2% to 5% under dynamic conditions and between 2% and 8% under static conditions. It is almost impossible for the O-ring diameter d1 to be less than 20 mm, so the stretching range must be wider. In order to minimize the range and maximize the stretch rate, it is necessary to minimize the tolerance of the groove diameter d3, and the requirement for the minimum O-ring stretch rate is not so strict. In dynamic applications, it is important to increase the maximum tensile rate to 5% or less to avoid harmful effects on sealing performance. Exceeding this value will cause a significant reduction in the cross section of the O-ring, which will affect the service life of the O-ring.

9 Axial installation, static movement

If the O-ring is used as a static axial seal, then the direction of pressure should be considered when selecting the O-ring size. If the O-ring is under pressure, the groove should be designed with the pressure applied, and the groove wall that the O-ring touches will always be far away from the side under pressure. If external pressure is present, the inner diameter d1 of the O-ring should be approximately 1% to 3% smaller than the inner groove diameter d8 when selecting the O-ring. If there is internal pressure, when selecting the O-ring, its outer diameter (d1+2*d2) should be equal to or about 1% to 2% larger than the outer groove diameter d7. When selecting a large O-ring with an inner diameter greater than 50 mm, the absolute outer diameter interference should be measured and minimized to avoid O-ring bending or slipping out of the groove during assembly. In addition, the ratio between the inner diameter and the cross section and the material of the O-ring should also be considered.

10 Initial compression amount

The initial compression of the O-ring cross section in the groove is critical to its function as a primary seal or a secondary seal element, which can: - Achieve initial sealing capacity - compensate for production tolerances - ensure specified friction - compensate for compression deformation - compensate for wear, depending on the application, the recommended initial compression is given below as a ratio to the diameter of the cross section (d2) : Dynamic application: 6 ~ 20% Static application: The dimensions of the 15 to 30% sealing groove can be designed according to the initial compression, these values follow the ISO 3601-2 specification, and take into account the relationship between the load and the cross-section diameter.

11 Compression Force

The compression force of the O-ring is variable and depends on other factors such as the initial compression amount, the type of material, the hardness of the material, the inner diameter of the O-ring and its cross section.

12 Groove filling

Considering the groove filling of O-rings, it is very important to avoid harmful effects on the performance of radial seals. The recommended trench filling ratio shall not exceed 85% of the thermal expansion or volume expansion due to fluid contact and tolerance effects.

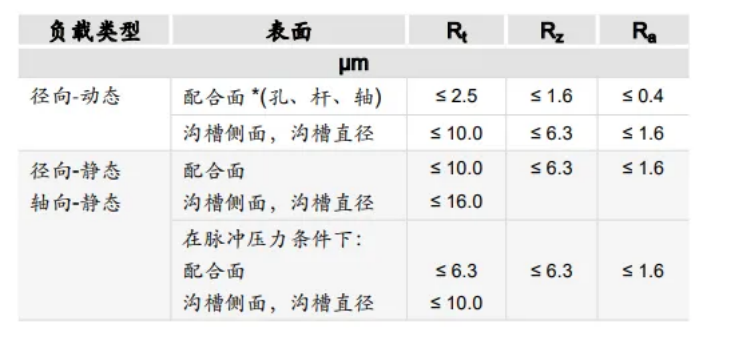

Surface finish of type 13 ring grooves

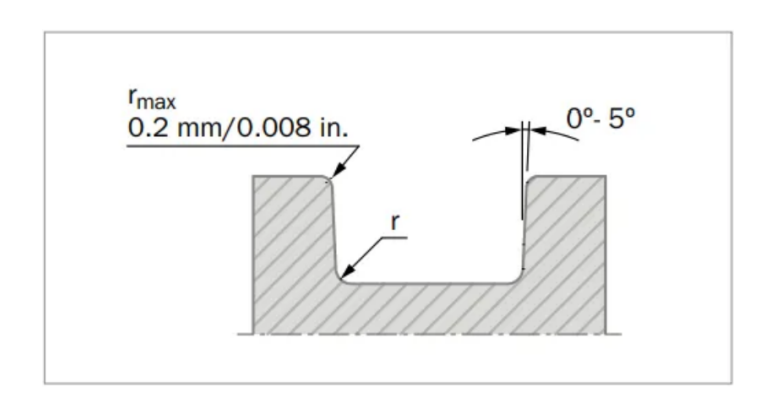

14 Rectangular grooves

Rectangular grooves are preferred for all new designs, and this structure allows for up to 5° bevels on both sides of the grooves. If a retainer is used, the vertical side must be used.

15 Recommended trench size

For information on radial clearance S and surface finish, please refer to "Groove Design and Dimensions". Groove width b2 and b3: When using a stop ring, the groove will be widened with the corresponding stop ring thickness (b2: one stop ring, b3: two stop rings). A fitting tolerance of H8/f7 is generally recommended.

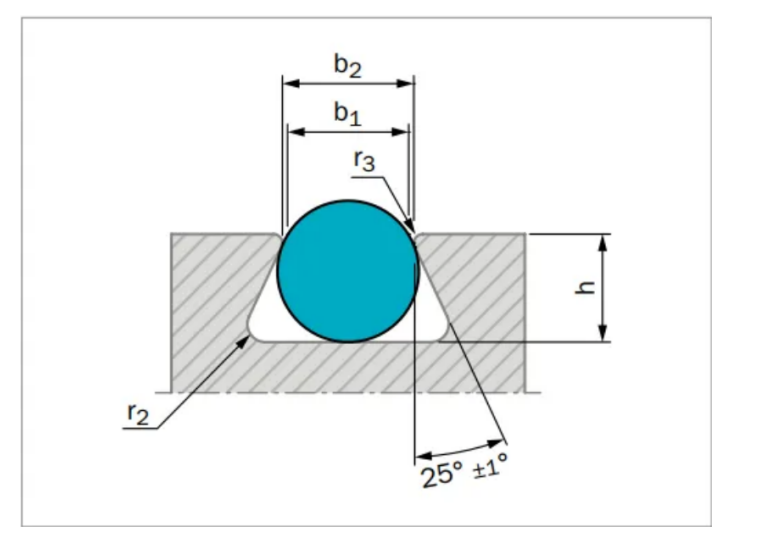

16 trapezoidal grooves

Trapezoidal grooves are used only in special cases, such as in top-mounted cases, in order to hold the O-ring in place. Trapezoidal grooves are only recommended for O-rings with a cross section diameter of 3.53 mm. The O-ring inner diameter is equal to the average groove diameter minus the O-ring cross section diameter.

The role of O-ring sealing is to seal the gap between the joint surface, isolate or cut off the leakage channel, increase the resistance in the leakage channel, or add a small work element in the channel, causing pressure on the leak, and partially offset or completely balance the pressure difference causing the leak to prevent the leak and achieve the effect of sealing.

Last article:Characteristics and application of EPDM rubber materials

Next article:What have we been doing all these years?