Summary of previous quality work

Release date:2024-08-12

Time flies, and the 6-month internship is coming to an end. During the 6-month internship as a quality engineer in the early stage, I gained a lot in terms of personal business ability, personal cognition and knowledge reserve. I summarized the early quality work from three aspects: early quality planning, early quality control and early quality improvement.

Early quality planning (APQP) starts from five stages: project feasibility analysis, product design, process design (rubber mixing process design, pre-forming process design, forming process design and post-processing process design), product and process confirmation, quality assurance and improvement.

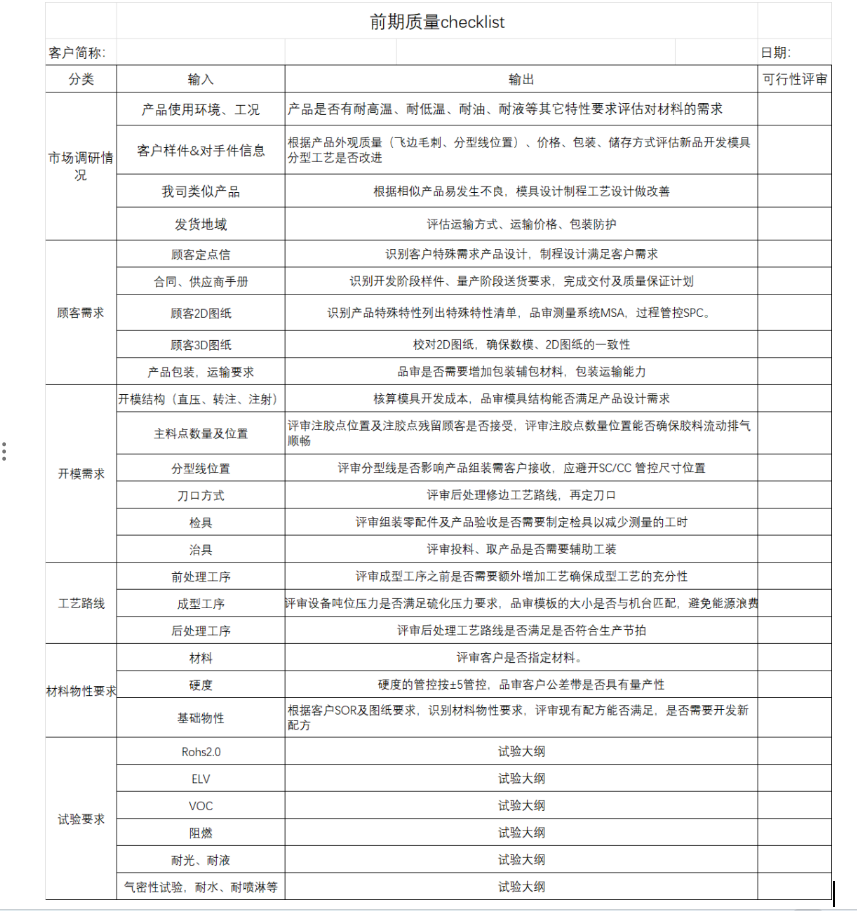

1. Project feasibility analysis

Input and output early quality checklist from the aspects of project background review, laws and regulations review, profit analysis review, technical capability review, development progress review, equipment and labor review, quality and logistics analysis review.

2 Product Design

The product is divided into material design and structural design.

At present, most of the products of Zhengcun are mainly processed by drawing, structural design is completed by customers, and Zhengcun mainly does material design.

2.1 Material design & Structural design

Ensure that the checklist items are fully considered in the design. Material design and structural design should consider the operability of mass production in addition to the terms in checklist. Requests for equipment, tooling and fixtures are presented. Simultaneously carry out mold and fixture fixture design, output DFMEA and mold design task book, etc.

2.2 Design verification plan

2.2.1 Material design verification plan

After communicating with customers, develop test plan and write test outline, complete test verification, and put into production after material release.

2.2.2 Structural design verification plan

The structural design is realized through the mold design. Generally, the processability of the product is verified through the soft mold design first, and then the mass production mold is developed. The structural design verification is determined by the full-size product report and the customer's actual installation results.

3 Process design

Process design of rubber refining process design (rubber refining process design is not introduced), pre-forming process design, forming process design, post-processing process design and control plan, output PFMEA, process flow chart, control plan, packaging plan, MSA analysis plan, initial process capability research plan (cpk, ppk) and work instructions.

3.1 Preforming process design

According to the distribution of the mold cavity of the product, the molding engineer cut the material manually, and the small batch test was verified to obtain the appropriate feeding amount and the shape of the rubber material to complete the preforming process design.

3.2 Molding process design

The molding process design selects the equipment with the tonnage meeting the requirements according to the mold design requirements, and chooses whether to increase the pre-treatment process according to the product characteristics and process characteristics. For example, Damper series is a product of the combination of plastic frame and rubber products. Considering that rubber and plastic parts cannot be degummed, adhesive should be used to paint the plastic frame, so the pre-treatment gluing process is increased.

According to the distribution of the product mold cavity, the molding engineer controls the weight and shape of the rubber material by hand cutting, and verifies the small batch test to obtain the appropriate feeding amount, the shape of the rubber material and the placement requirements to complete the preforming process design and the molding operation. The three elements of time, temperature and pressure suitable for product vulcanization were obtained by small batch test. Improve the appearance defects of products through trial process, obtain qualified products, improve process records and obtain process fine-tuning records.

3.3 Post-treatment process design

The post-treatment process design is divided into five major items: manual trimming, machine trimming, secondary vulcanization, gas test, eye test and packaging, and some combinations of them are selected according to actual needs.

3.3.1 Trimming edges manually

After the product is molded, hot repair or cold repair is determined according to the actual trimming state. Select the appropriate tool, trim the edge, through many attempts, select the most reasonable trimming hand, and develop the trimming work instructions.

3.3.2 Machine trimming

According to the tool edge design, choose the appropriate machine trimming method. There are three types of machine trimming: centrifugal trimming, freezing trimming and punching trimming. Through continuous debugging, the best process parameters are obtained, and the trimming operation instruction is completed.

3.3.3 Secondary vulcanization

Peroxide vulcanization products and silica gel products will increase the secondary vulcanization process. In order to prevent product deformation, find the best placement requirements by doing trial verification.

3.3.4 Gas test

Determine whether additional gas testing process is required according to product characteristics. For example, Panasonic washing machine drainpipes have sealing requirements, and the product needs to increase the gas detection process to control the air tightness. Design gas inspection equipment, the product after installation under a certain pressure of air pressure

The product is inflated, and whether the air tightness of the product meets the design requirements is judged by the pressure holding situation.

3.3.5 Eye inspection

After the product trimming, the post-treatment inspector will check the appearance quality of the product, and the quality engineer will formulate the inspection standard and the release standard of the limit part.

3.3.6 Packaging

The quality engineer in the early stage shall formulate the packaging plan according to the customer's packaging and transportation needs. In the case of no special requirements of customers, we seek low cost and high packaging efficiency.

The formulation of the post-treatment process can be combined according to the needs of the production line process route, such as the repair package process route, the molding and trimming process route and the post-treatment package inspection process route.

4 Product and process confirmation

4.1 Mass production test, sample inspection, trial process acceptance (pre-forming process, molding process, vulcanization process, post-treatment process), limit sample formulation is completed by the early quality.

The full size measurement of molds and samples meets: the principle of centering and the principle of standard deviation 1/6.

* Alignment principle: Dimensions are measured in the middle band of tolerances

*1/6 principle: Data stability meets standard deviation ≈1/6 design tolerance

4.2 MSA analysis of the measurement system to analyze whether the measurement system can meet the requirements of measurement monitoring. Analysis of process capability ckp and ppk to meet control standards.

4.3 Output CP and SOP.

5 Quality assurance and improvement

5.1 Do dynamic management of PFMEA and control plan, identify new risk points and update PFMEA, control plan and related three-level documents.

For example, when a new anomaly occurs in the production process, the failure mode is analyzed, and the cause of the anomaly, improvement countermeasures and preventive measures are updated to the PFMEA and control plan after the anomaly is closed. Update work instructions to ensure the adequacy and appropriateness of work instructions.

5.2 Project phase meeting summary to ensure continuous improvement

Our company (4) the project phase points T/T (3), T/T (2) (1) and T (0), T (1), T (2), T (3) eight stages. The specific work requirements and tasks of each stage are not introduced. In order to ensure quality and continuous improvement, the project team can only advance to the next stage after the completion of each stage. The operation of the project is managed in three sets: the project progress board, the agenda and the project problem list. The technical problems are recorded in the project problem list and the task arrangement is recorded in the agenda to ensure the project progress.

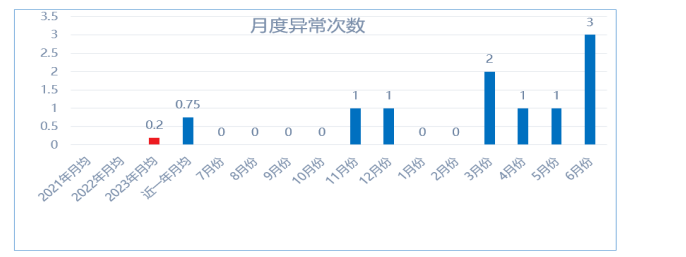

5.3 Summarize the abnormal quality planning in the early stage every month

5.3.1 Monthly Abnormal Count

5.3.2 Monthly Abnormal Repeats

(omitted)

5.3.3 Monthly Exception Analysis

(omitted)

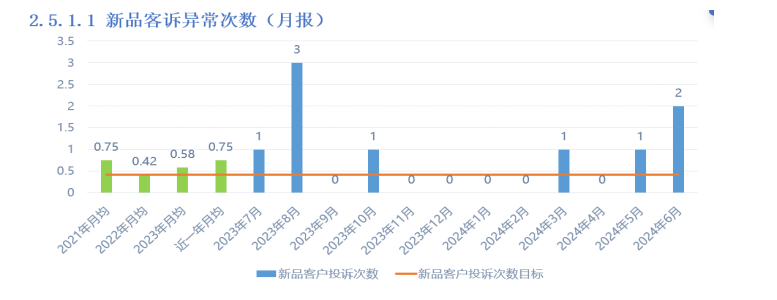

5.4 Develop KPI for performance appraisal

5.4.1 Number of customer complaints about new products (monthly report)

5.4.2 Number of Structural Design Anomalies (Monthly Report)

(omitted)

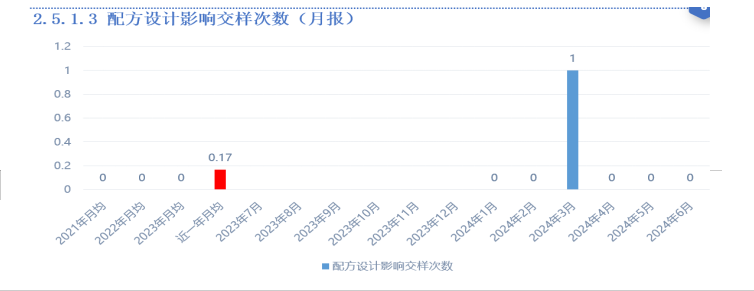

5.4.3 Influence of formula design on sample delivery times (monthly report)

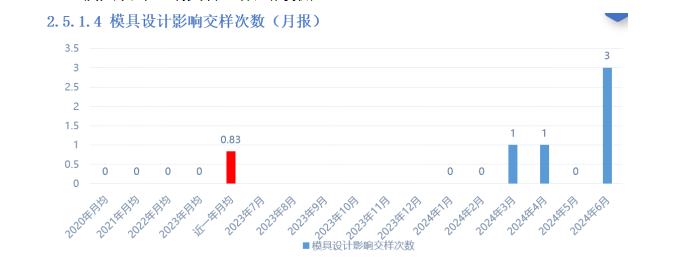

5.4.4 Mold design influences sample delivery times (monthly report)

5.4.5 Influence of molding design on sample delivery times (Monthly report)

(omitted)

Last article:What have we been doing all these years?

Next article:New equipment new atmosphere