Planning of automated warehouse

Release date:2024-12-16

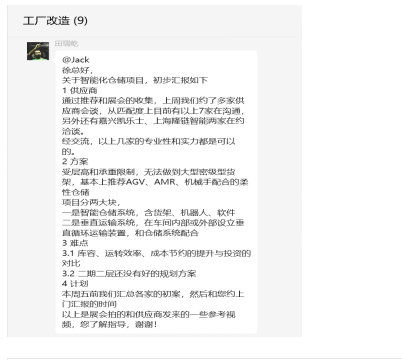

With the rapid development of science and technology, the application of automation technology in warehouse management is increasingly extensive, which not only changes the status quo of warehouse operations, but also brings higher efficiency and lower operating costs for enterprises. This coincides with the management philosophy of Zhengcun for many years, and the automated three-dimensional warehouse project of Zhengcun has also been put on the agenda.

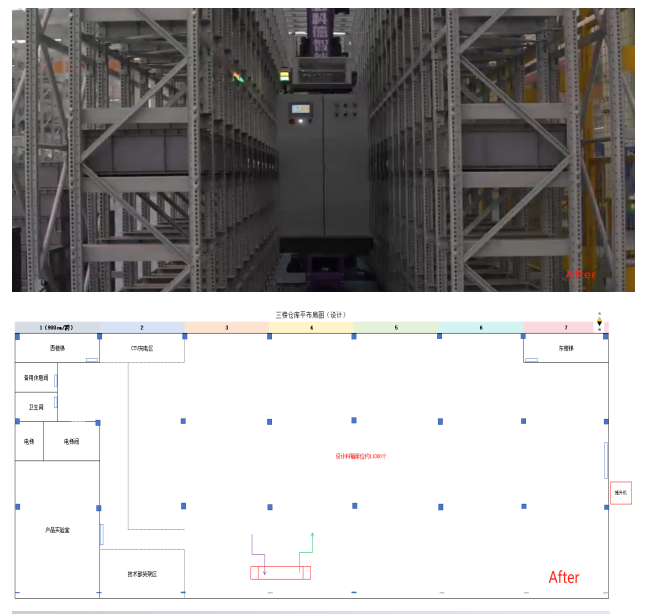

Automated three-dimensional warehouse is a new concept in logistics warehousing. The use of three-dimensional warehouse equipment can realize the rationalization of high-level warehouse, access automation and simple operation. Automated three-dimensional warehouse is a form of high technical level at present. The main body of the automatic three-dimensional warehouse is composed of shelves, roadway type stacking cranes, in (out) warehouse workbench and automatic transport in (out) and operation control system. The shelf is a steel structure or reinforced concrete structure of the building or structure, the shelf is the standard size of the cargo space, the roadway stacking crane through the roadway between the shelves, to complete the storage, pick up the work. The management adopts computer and scanning code technology. Compared with the traditional flat warehouse, the automatic three-dimensional warehouse has significant advantages in space utilization and cargo handling efficiency.

At the beginning of November, the company immediately arranged relevant colleagues to participate in the Asia International Logistics Technology and Transportation System Exhibition. With our needs and ideas, we had a preliminary understanding and communication with automated warehousing exhibitors at the exhibition, which laid the groundwork for further negotiations in the future.

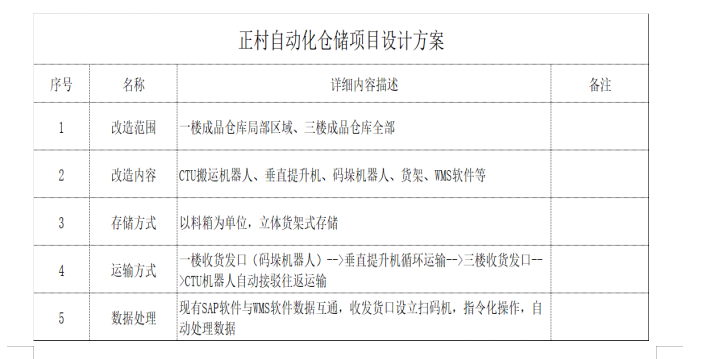

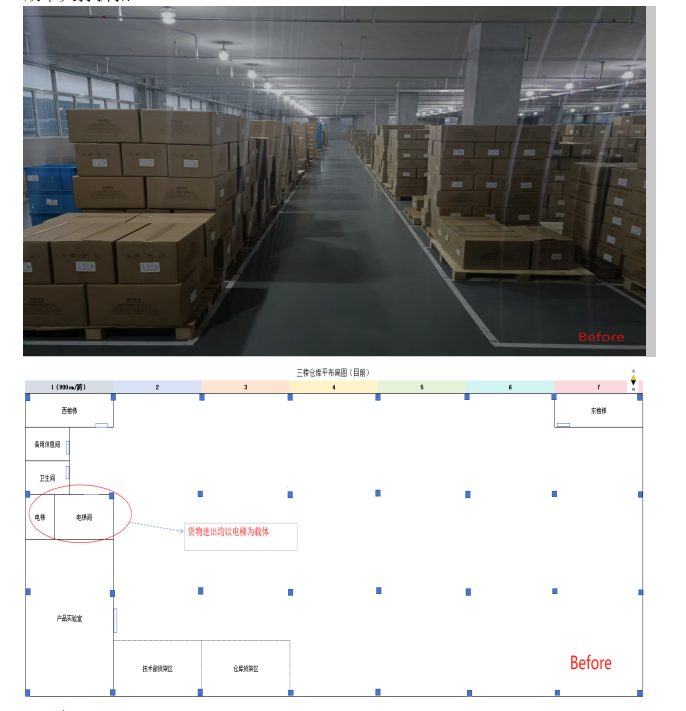

1 Status Quo

At present, the management mode of our finished product warehouse is tiled warehouse location management. In order to ensure the first-in-first-out of the product, the warehouse keeper needs to shuttle back and forth between the various warehouse locations to carry out cargo sorting, tallyand picking, which is very time-consuming. At the same time, the owner of the product up and down the floor has to rely on a freight elevator, which wastes a lot of waiting time every day, which greatly reduces the work efficiency of the warehouse keeper.

2 Outlook

After the introduction of automated three-dimensional warehouse, the third floor finished product warehouse will be built into a closed storage space, and the operation of warehouse managers will be concentrated on the first floor. When the product is stored, the scanning code is completed, and the vertical elevator transmits the goods to the third floor, where they are stored by the stacker on the third floor to the designated location. When taking the product, the warehouse keeper only needs to enter the required product number and quantity in the terminal, the system will direct the stacker to quickly and accurately take out the product from the warehouse, transported by the stacker to the elevator, and then the product is taken out from the shipment port by the palletifier to complete the palletification, the whole process does not need manual intervention, greatly improving the efficiency of storage and delivery.

In addition, the automated three-dimensional warehouse also uses Internet of Things technology and big data analysis to achieve real-time monitoring and intelligent management of goods. Through the monitoring system, managers can grasp the inventory situation and work progress of the warehouse at any time, so as to make quick and accurate decisions.

We firmly believe that after the completion of this project, we will bring a new level of warehouse management, bring higher efficiency, better quality and lower cost for warehouse management, and enhance the company's market competitiveness.

Last article:Mingdao Cloud super application platform launched

Next article:Talk about the need for a return check